We were recently asked by a homeowner how to finish the edge of an asphalt driveway. If you are repairing part of your asphalt pavement and the repair involves the edge of the pavement, there is a correct way to finish the edge to help keep it structurally strong and durable.

Unlike concrete, where forms are used to contain the concrete until it cures and to give it its edge, asphalt material requires a different installation method. Properly finishing and compacting an asphalt edge is very important to the adhesiveness of the materials in the asphalt and the edges overall stability.

Unlike concrete, where forms are used to contain the concrete until it cures and to give it its edge, asphalt material requires a different installation method. Properly finishing and compacting an asphalt edge is very important to the adhesiveness of the materials in the asphalt and the edges overall stability.

Asphalt is a flexible paving material that is capable of forming a solid and durable driveway surface when properly constructed. If you’ve ever seen an old asphalt street being removed, it was probably being removed by heavy duty machinery with a large scoop bucket on the front of it breaking up the old asphalt material as it moves along. Concrete on the other hand is a non-flexible material. It would require tools like a jack hammer, a concrete saw, and a sledge hammer to break it up.

Since asphalt is a flexible material, the edges of asphalt pavement need to be properly constructed and contained. In some situations, the edge of an asphalt driveway will butt up against a hard surface like a concrete walk or the concrete street curb. The hard surface of the concrete acts as a stable vertical support and containment for that edge of the asphalt pavement.

Most edges of an asphalt driveway typically run along a lawn area or a plant bed. In this case, where there isn’t an adjacent structure like the concrete walk, the asphalt material needs to be constructed and finished in a different way to give it a durable edge to help make the material resistant to cracking and disintegrating.

One of the ingredients in an asphalt mix is small aggregate, and if the asphalt material is not properly contained and compacted, the aggregate can loosen from the glue-like asphalt binder and result in an ongoing deteriorating situation.

What Makes a Durable Edge?

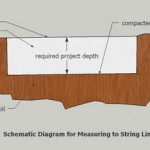

The correct way to construct the edge of the asphalt adjacent to the lawn or other such areas involves the base material also. Make sure the aggregate base that supports the asphalt material is extended 6 inches beyond the edge of the asphalt. This provides a sufficient surface area for the asphalt to retain its form and protect the edges from damage and deterioration.

Detail of a properly constructed asphalt edge

When asphalt is placed, the main portion of it is rolled with heavy equipment to compact it and obtain a smooth surface. The compaction gives it its finished form and allows the asphalt to become a hard and durable surface after it has cured. After the asphalt is rolled, the edges of the asphalt are finished by tamping them back at a 45 degree angle with a tamping tool to compact the materials in the asphalt, and to give the edge a stable form.

Tamping the edge to the optimum angle (45 degree) gives strength and stability to the asphalt edge. When the edge of the asphalt pavement is properly cured, this angle will provide a durable containment edge, also.

Typically, the base depth for a residential asphalt driveway is 8″. Check with your local building department to comply with local building code.